City Companion

Loaded, Folded & Carried as a Tote

Design & Analysis

New product design requires a systematic approach that typically balances eye appealing symmetry, product performance and structural stress minimization, while maintaining low cost and weight. The process begins with creativity, innovation and preliminary analysis. Initial analytical results provide insights necessary to refine concepts to optimize structural stress. Based on decades of providing novel product solutions, theoretical expertise and engineering experience for our government, Waveony staff down selects readily fabricated concepts for detail design/analysis optimization, prototype fabrication and testing.

At Waveony we embrace the power of collective creativity, encouraging our engineers and designers to contribute concepts, variations on concepts, “in the box” and “out of the box” creations. During this initial brainstorming stage our team brackets the product design envelope and initially evaluates a wide range of product geometries, performance ranges, features, symmetry and balance. Initial finite element analytical results (FEA) offer insights as to how different concepts structures react to applied loads, identifies structural load paths, and high stress locations.

Finite Element Analysis Hole Stress

At this stage in product development the most promising designs are selected for further design and FEA refinements. Primary concerns focus on resolving high stress locations through a variety of geometric, material and assembly techniques. Hole stresses (illustrated to the left) are often of interest as loads are typically transferred between components via fasteners. Fasteners, such as rivets and bolts require holes, these holes and/or fasteners are usually locations for high stress. Finite element modeling refinements minimize hole stresses, to reduce high stress, which prolongs the useful life of a structure.

Down selection of the final product design, most often, is a compilation of different components from competing product designs. Selection of components for the final design meet product performance specifications, ensures an appealing design, and meet cost/ weight requirements. Following final design down selection, our team begins with detailed design, analysis optimization and concludes with the generation of drawing packages for fabrication.

Existing product design variations, such as altering the length, width and/or height, typically does not require additional design and/or analysis. This is because during product detail design/ analysis parameters of a design are bracketed, which permits changes in product geometry and/or load cases to be readily implemented. For example, if a customer has interest for a cart to fit a specific onboard stowage volume, Waveony personnel will create in CAD (Computer Aided Design) that specific volume and very quickly modify an existing Waveony Wagon to fit. A fabrication drawing package is generated and sent to our Custom Cart department. Our Custom Cart group cuts, drills, bends and assembles each custom cart.

All of our carts are fabricated right here in the USA!

Material Selection:

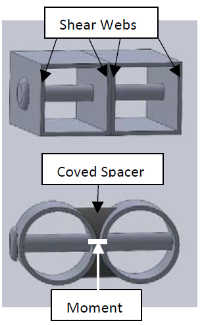

After purchasing a Waveony cart, one will notice several differences in material selection. Carts are fabricated with highly corrosion resistant aluminum grades for all frame components. We use lightweight square tubing rather than round tubing like our competitors. Square tubing is more difficult to use in fabrication and therefore more expensive. Since every cart is an assembly of components, square tubing is much more efficient at transitioning stress across a riveted joint than round tubing. This is because the side walls of a square tube act as shear webs to transition the load. Joining two round metallic tubes requires use of a coved spacer(s). Coved spacers create a moment across the joint the thickness of the spacer (see illustration at right). In addition these spacers are almost always plastic. Aluminum has a strength of approximately 44,000 psi versus nylon 6/6 (coved spacer) of only 12,000 psi. This is almost 4 times less!!! Combining this moment with a much more elastic material, like nylon, significantly reduces the load carrying capability of this type of structure. Which is why Waveony carts are fabricated with square tubing and therefore why they can haul up to 340 lbs. of gear!

Load bearing capability of assembled structures are typically determined by joint design. Waveony carts are no exception. Rivets perform well in shear, not so in tension. For this reason Waveony carts are designed to maximize the shear load and minimize the tension load that load bearing rivets react. In addition our carts are designed with a clear load path to minimize cart structural stress, which reduces weight and ultimately cost. Another discerning factor of our carts is the use of semi-tubular rivets versus blind rivets. Semi-tubular rivets distribute stress across the entire width of each tube, therefore distributing stress over four shear webs. Whereas blind rivets only distribute stress over the two adjacent webs to be riveted, which halves the area that stress is distributed. Halving the area directly results in an increase in stress across the riveted joint. Increasing stress reduces a riveted joint’s load carrying ability. Use of semi-tubular rivets also maximizes rivet shear strength. Semi-tubular rivets are solid aluminum along the length of the rivet until the end, where a hole is bored into the end for the purposes of clinching the rivet. The depth of the end bore varies with rivet diameter. For example on a 0.25” diameter x 2.5” long semi-tubular rivet, the hole bored into the end is just 0.219” deep. A solid rivet has greater shear area than a hollow rivet, which directly translates into greater load carrying ability and long service life. Use of semi-tubular rivets are also more expensive than blind rivets, this additional cost is minimal when one takes into consideration the significant reduction in joint stress and the designed life of these carts of decades.

1000D Cordura nylon is used to make up the bags. This 100% nylon heavy weight fabric has excellent tear strength and is exceedingly abrasion resistant. This fabric is very tough, durable and versatile. To demonstrate the load carrying ability of this material, we packed our carts with steel pigs for static load and creep testing. Below, under Prototype Testing, are tests Waveony staff performs to validate cart performance.

Nylon rims are used to eliminate the potential for rust. Pneumatic tires with tubes are standard and offer the lightest weight and lowest cost.

Prototype Testing

Waveony conducts prototype testing to validate that each design meets performance requirements, meets customer expectations and to correlate test results with analytical results to refine FEA models.

Maximum Static Load & Creep Testing: This static load test demonstrates that the carts our customers receive will actually haul 150 lbs. for the City Companion and 340 lbs. for both the Haul’n Cruiser and Mega Hauler. We load up each cart with steel pig weights (steel pig weights are solid rods of steel) and haul it over docks, walkways and gravel parking lots to validate performance. After this, begins the start of the creep test, where the steel pig weights are left in the cart for 3 continuous days. What is creep? It is the deformation of a structure to stress over time, also referred to as the creep rate. At Waveony this test is performed to assess overall structural performance to react stress and more particularly, the ability of highly loaded joints to react a sustained load over time. At the conclusion of the 3 days, the carts are once again hauled around a gravel parking lot, docks and walkways to validate performance.

Partial Load Drop Testing: Always place items in any cart during loading. It is dangerous to let go/ drop heavy items into any cart. Ask for help placing a heavy load. Why is this dangerous? Because the wheels and kickstands support a loaded cart. If during placement of a heavy item, it falls or slides/ shifts causing the load to land on either end of a cart, it could cause the other end of the cart to suddenly rotate upwards impacting the user. Waveony personnel perform this test in a controlled environment with safety equipment in place. We perform this test to understand what happens if a customer accidentally loses their grip and lets go causing a load to fall into one of our carts.

Folding & Unfolding Testing: Waveony’s patent pending designs allow our carts to fold and unfold for light loads. This test is performed for loads greater than an average person can safely lift with one hand. We test our carts with a 75 lb. load. We want to be certain that our customers can safely open and close their loaded carts. For this reason we have created a video located on the home page. This video demonstrates the best way to unfold or fold an unloaded or loaded Waveony cart.

Ease of Handling: Waveony personnel test cart handling characteristics using one handle extended and both handles extended. The test includes navigating through doorways, gates, down/up ramps, traversing slopes, along docks, sidewalks, across gravel parking lots and around the inside of a house. Handle design, low center of gravity and wheel placement permits Waveony’s carts to be easily navigated around obstacles. For light loads when pulling the cart, navigate around obstacles as one would with rolling luggage, simply by steering the cart behind or to the side. For heavy loads always push the cart in front of you.